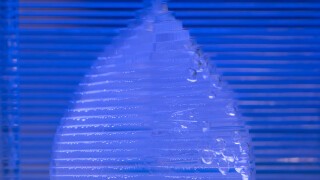

Additive manufacturing for defence technology

3D printing applications for military technology will be the subject of a session at the Innovations in Additive Manufacturing forum on 15 May 2024 at Rapid.Tech 3D

175 Following Show all