Electron beam powder bed fusion (EPBF) is a technology with potential. FREEMELT ONE is an open-source system for materials research to enables many more materials than currently available in additive manufacturing.

Fusion energy has long been seen as a potential solution to the world’s energy problems as it could offer a nearly limitless source of clean energy. The conditions required for the fusion reaction to occur are extreme including extremely high temperatures and intense radiation. This put great demands on the materials used in the fusion reactor, in particular on the materials for so-called plasma-facing components.

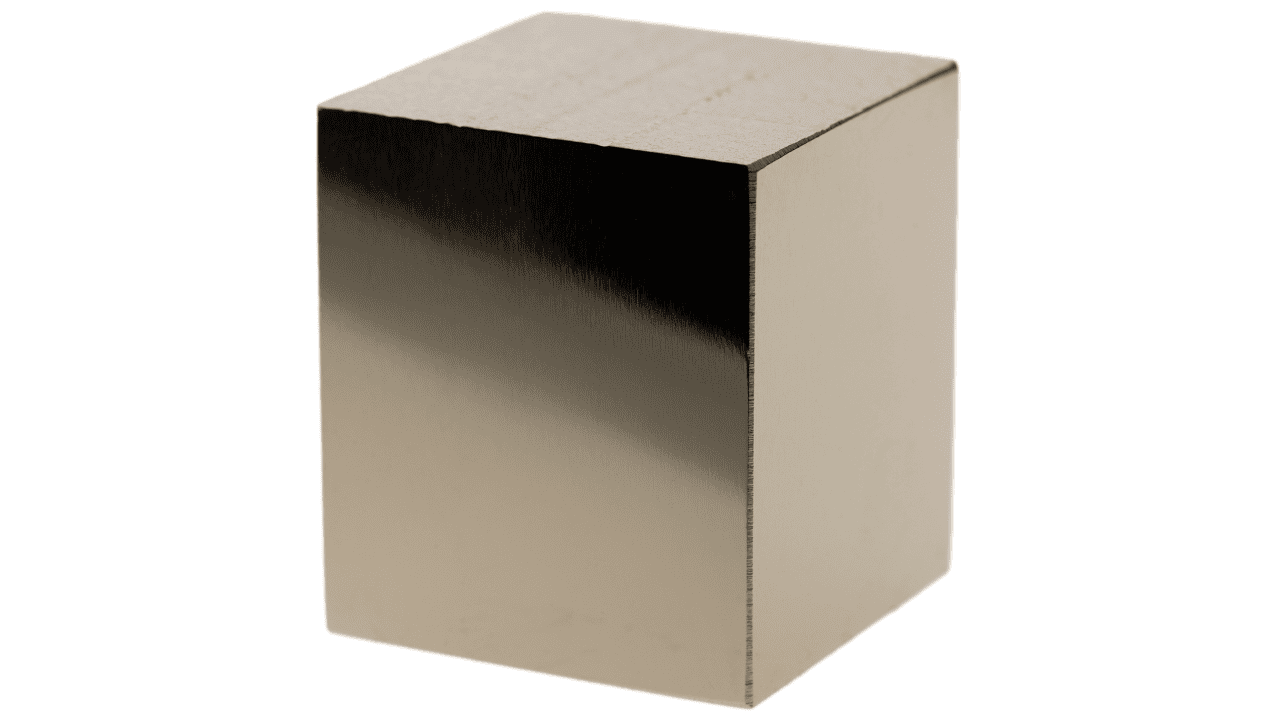

Pure Tungsten is currently the most interesting candidate to be used in these parts of the fusion reactor. It is a difficult metal to process due to its extreme melting temperature and poor ductility which has limited the possible application areas and manufacturing methods in the past.

Electron Beam Powder Bed Fusion (E-PBF) is an additive manufacturing technology operating at high temperature under vacuum conditions. It has so far been the only additive manufacturing technology that has been able to print fully dense, crack-free, bulk samples of pure tungsten. Freemelt has developed a fast process for printing dense tungsten parts which we will show in the presentation. Furthermore, we will show the special technical features of Freemelts additive manufacturing systems making it possible to print dense tungsten parts at high rate.

Presentation language: ENG