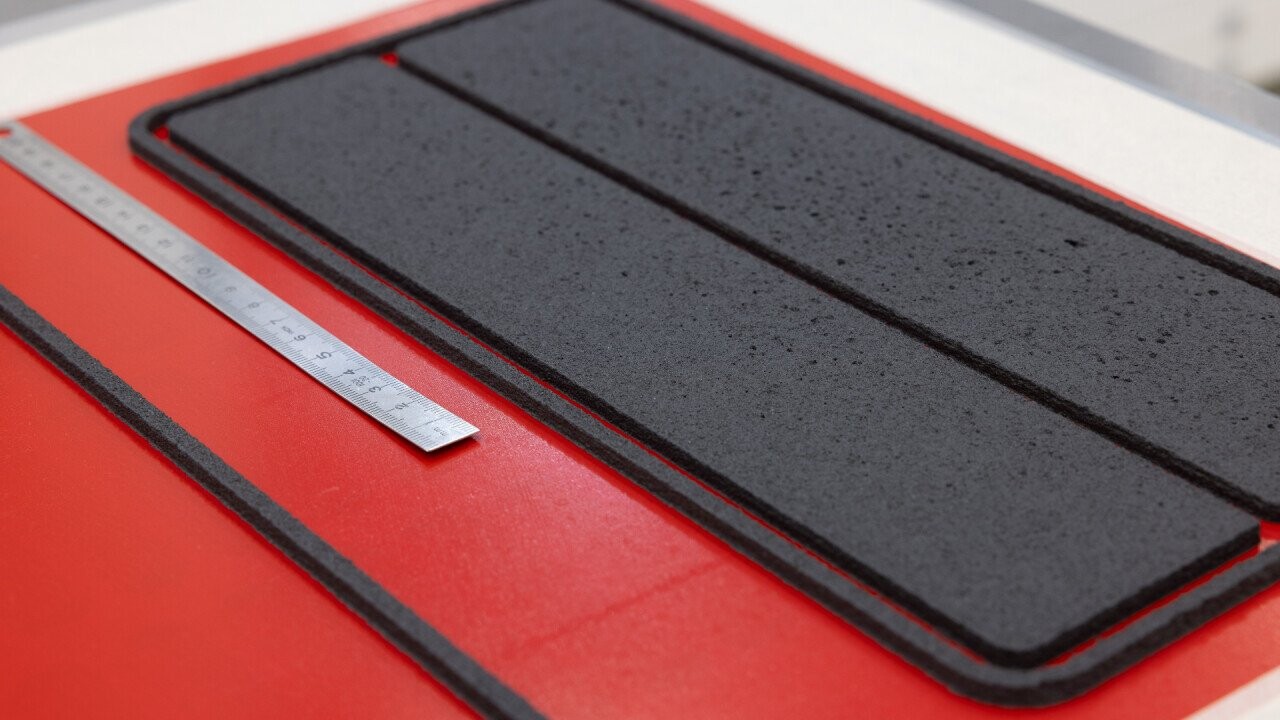

WHITECELL POWER AG reports on how graphic bipolar plates are used in fuel cells and how hydrogen is electrochemically converted into electricity. Bipolar plates and their blanks can be produced quickly and individually using the screen printing process.

Screen printing has been known for many years and is basically a 2.5d printing process. Very fine structures can be produced using special screens. By selecting suitable materials and adapting the process accordingly, electrically conductive and mechanically sealed components can be produced.

The Whitecell Group produces these bipolar plates and connects them to form stacks. These stacks supply electricity from hydrogen.

Screen printing is not a trivial process; as with other AM processes, it is absolutely essential that the source material, process preparation and process adaptation (times, temperatures, speeds, oven processes, post-processing) all work together.

Together with the machine manufacturer Exentis, Whitecell is developing processes within the Group in order to offer customers (internal and external) added value.

The bipolar plates are then used in fuel cells, among other things, which are assembled into stacks. These stacks are already being tested in real vehicles. These vehicles can then be used to drive in cities where combustion engines are no longer permitted and purely electric vehicles have too short a range. The vehicles can also be Whitecell fleet vehicles.

Presentation language: GER