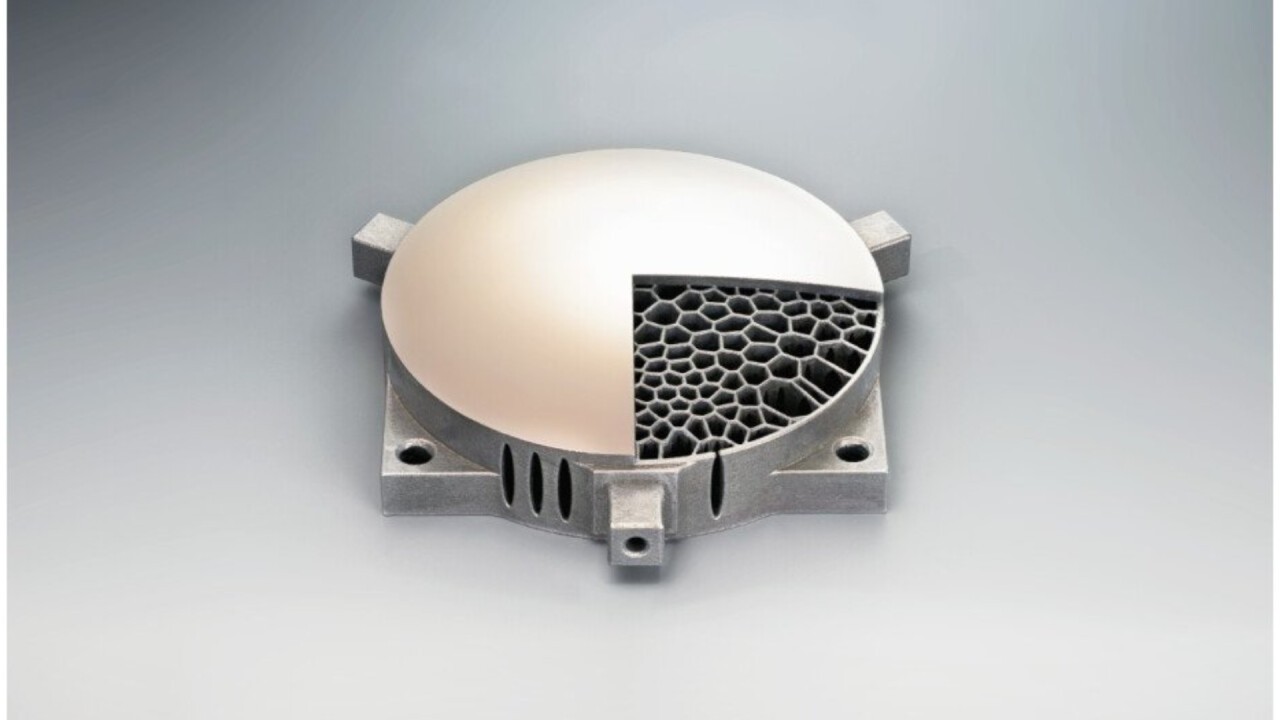

The benefits of the additive manufacturing (AM) process are used for extreme lightweighting and tailored mechanical properties of metal optical components like mirrors or housings

The benefits of the additive manufacturing (AM) process are used for extreme lightweighting and tailored mechanical properties of metal optical components like mirrors or housings. Especially for space projects as the main area of application, the whole manufacturing chain has to be proven as highly stable and reproducible.

The choice of the AlSi40 base material for the mirrors is closely linked to the used manufacturing chain. After AM manufacturing, additional processing steps like diamond turning, plating with electroless nickel, figure correction, polishing and coating with a high reflectivity layer are required. The AlSi40 material is matched to the CTE of the polishing layer which avoids thermal induced deformations of the high-quality surfaces. Final shape deviations of below 150 nm PV (Peak to Valley) and surface roughness of below 2 nm RMS (Root Mean Square) are achievable.

The talk highlights the potential of the technology for space applications but also the remaining challenges like defects, contaminations, or surface roughness. Other areas of application such as lithography or laser material processing are also addressed. Exemplarily results of different projects will be presented.

Presentation language: GER