The presentation discusses the qualification and production of the high-performance aluminum alloy AHEADD® CP1. The actual material characteristics of AHEADD® CP1 in an automotive application are also covered.

Autonomous and environmentally friendly vehicles are set to play a crucial role in the future of urban mobility. The EDAG CityBot is a multifunctional robotic vehicle that can be adapted to various transportation tasks through the use of towing vehicles and interchangeable add-on modules. These tasks include transporting people, moving goods, and cleaning paths and parks.

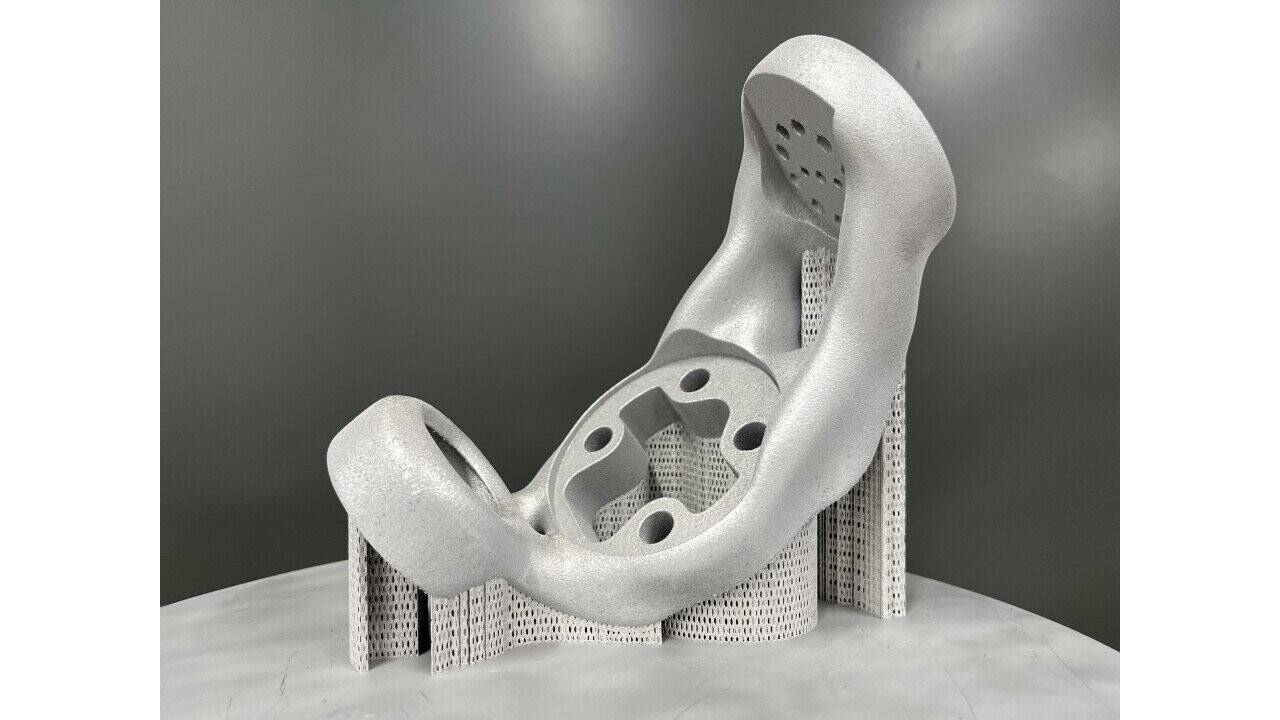

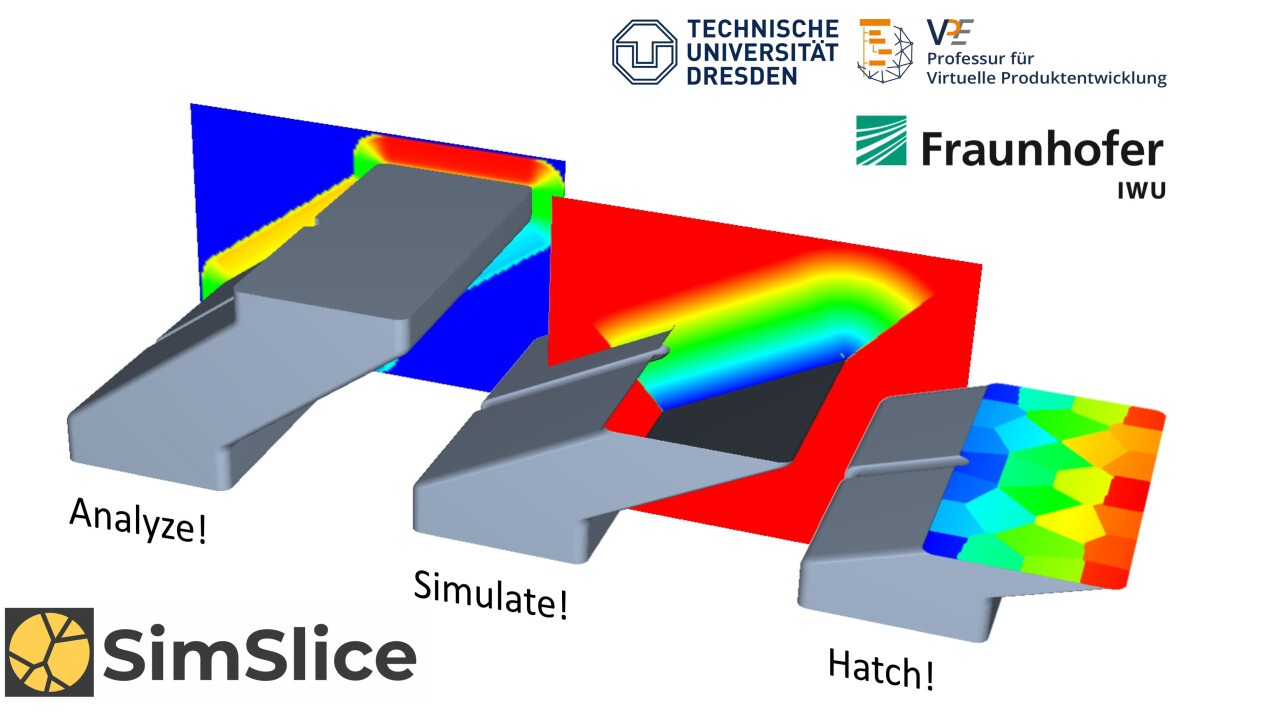

EDAG, Constellium and Fraunhofer IWU will present a process chain for automated rapid component development and selection of the most suitable manufacturing process and material. The wheel carrier component of the CityBot was chosen as a demonstrator. It is a multifunctional load-bearing component that connects the chassis with the wheel and steering motors. Different transportation tasks and corresponding loads require a flexible and fast adaptation of the part design.

Laser Powder Bed Fusion (LPBF) in combination with Constellium Aheadd® CP1, an aluminum alloy specially developed for the LPBF process, has proven to offer economic and technological advantages. It offers maximum flexibility for the given requirements in terms of very good processability, high and robust mechanical properties and highly productive processing.

Presentation language: ENG