Use Case / Showcase Rapid.Tech 3D 2024

Process optimization with additive manufacturing

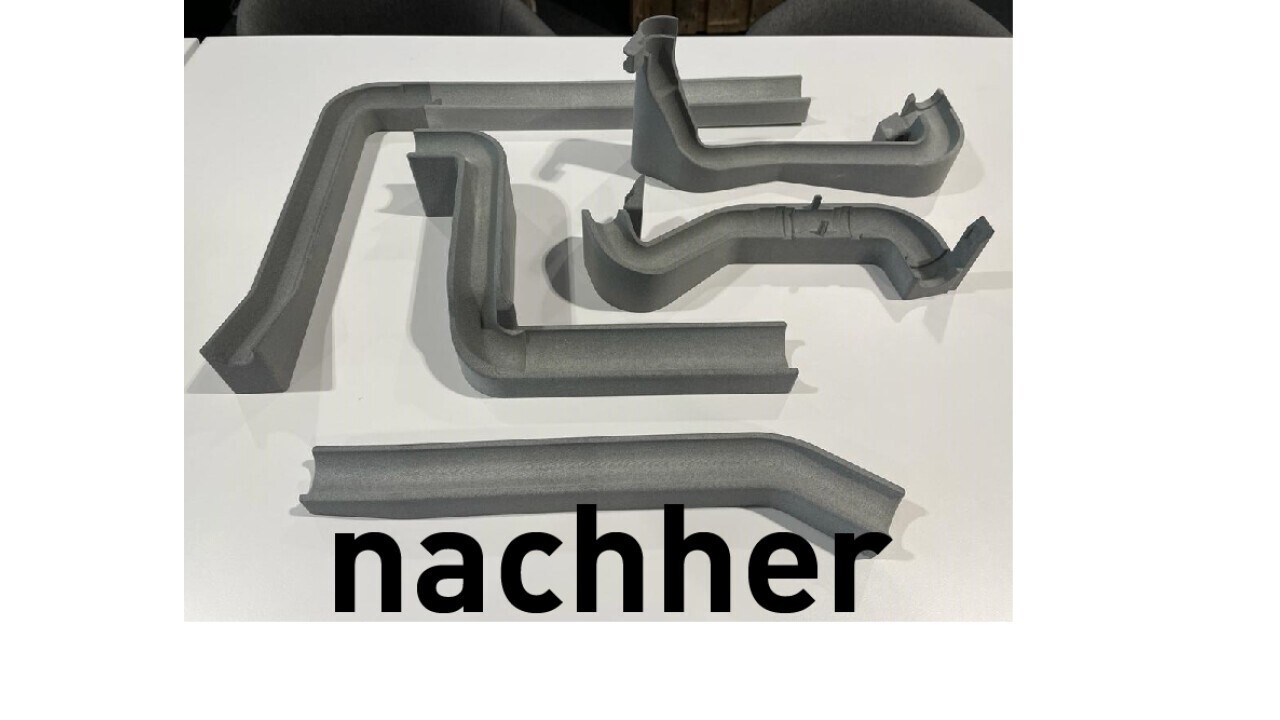

Every company must face the challenges of increasingly efficient and sustainable production. The possibilities of additive manufacturing can be used to solve the complex issues of process optimization.