HP Multi Jet Fusion (MJF) is a fast and economical 3D printing process in plastic printing for extremely high-quality prototypes, functional and series components.

The technology, in combination with selected materials, guarantees individual high-end components in reproducible quality. With the latest device generation HP Multi Jet Fusion 5210, SPÄH also offers decisive advantages in the area of series production.

In addition to the material polyamide 12 (PA12), with high stability and impact resistance, we also offer the rare combination of MJF technology and the material polypropylene (PP). Polypropylene is characterized by chemical resistance, ductility and elasticity.

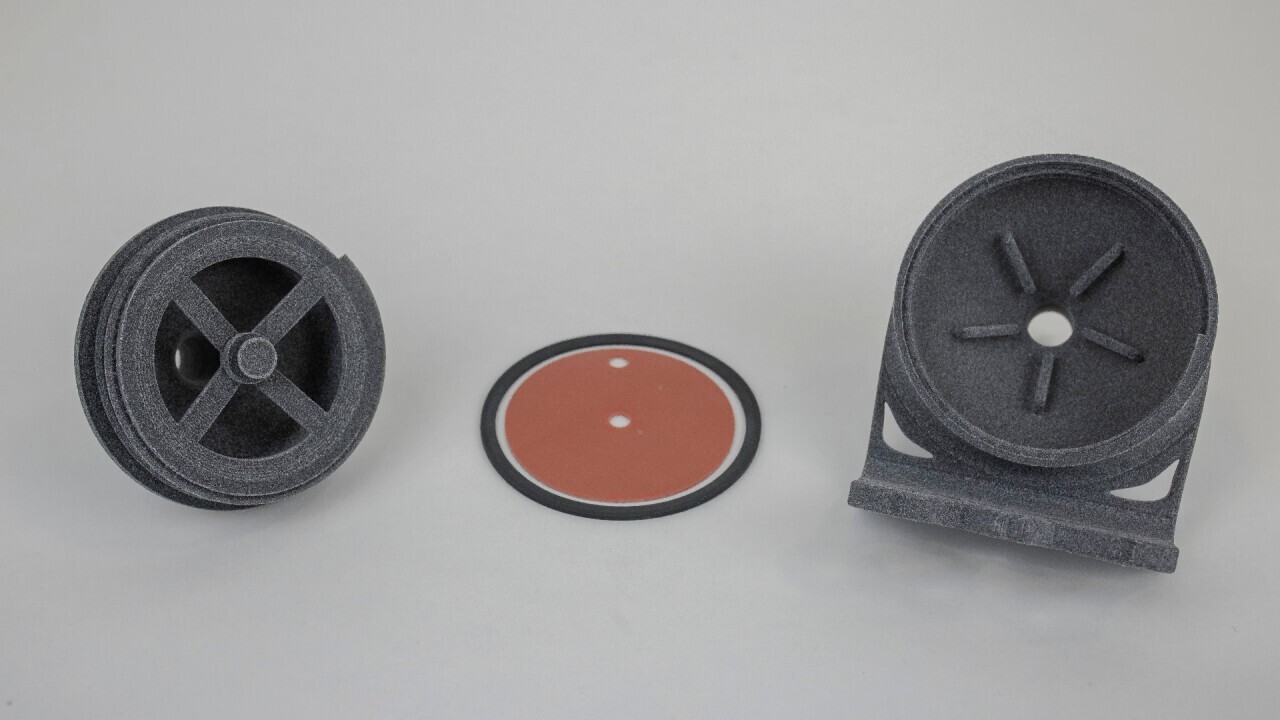

Using the example of a drain module printed from PP, we show product requirements and advantages of the new product variant compared to the old component:

Requirements:

- climatic material testing

- Rapid and extreme temperature fluctuations (condensation)

- light water flow - strong water flow

- Pressure and water quantity vary

- Module should be semi-permeable, no external air supply

Advantages over the old module:

- 4 individual components - previously 14 individual components

- 2 materials PP and rubber - previously a material mix of plastic, metal, rubber

- 1 supplier - currently 8 suppliers

- 1 order position - previously 8 order positions

- Elimination of pre-assembly

- No risk of corrosion - previously possible with metal components

Scouting competence:

- 1 system supplier no

- Material competence and manufacturing technology

- Short delivery time

- Reduced costs

- Process optimization

As a leading, Europe-wide expert in rubber and plastics processing, the SPÄH-Group of companies offers a wide range of processing methods, large storage capacities and an almost endless variety of materials. SPÄH is also one of the most innovative companies in the field of additive manufacturing.