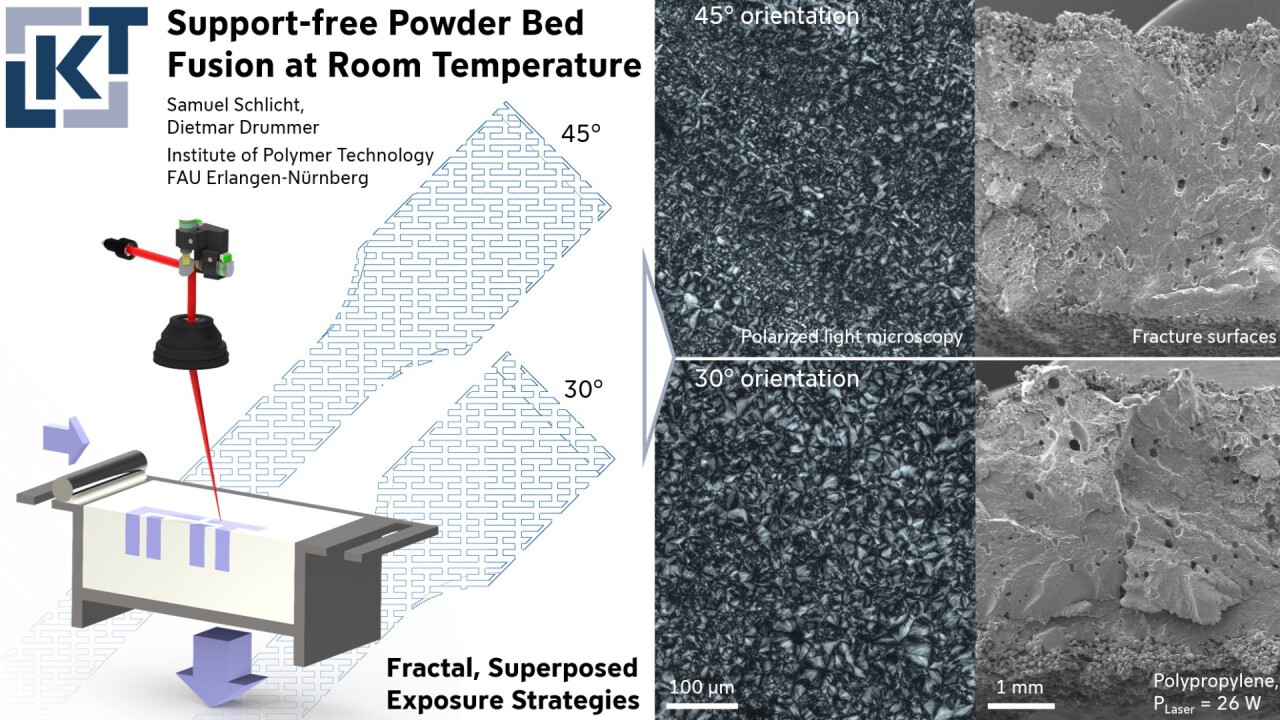

The presentation of Samuel Schlicht (FAU) will be the first to demonstrate the production of polypropylene components at room temperature using selective laser beam melting without the need for support structures or high ambient temperatures.

The laser-based powder bed fusion (LPBF) of semi-crystalline polymers enables the support-free layer-wise manufac-turing of geometrically diverse, complex components. In contrast to the established quasi-isothermal powder bed fusion of polymers at elevated temperatures, non-isothermal, cold processing strategies allow to significantly extend the range of applicable material systems. Relying on the superposition of discretized, fractal exposure strategies and the implicit mesoscopic compensation of crystallization shrinkage, the support-free LPBF of polypropylene at room temperature is demonstrated. The present paper displays the temporally and spatially discrete exposure of superposed fractal, space-filling curves, enabling the support-free LPBF of polypropylene through combining the mesoscopic compensation of crystallization shrinkage and the laser-induced minimization of thermal shrinkage through the implementation of pre-exposure scans. The non-isothermal processing regime was observed to exhibit an intrinsic robustness towards the influ-ence of processing parameters on emerging peak temperatures while showing a significant extent of accumulated heat within manufactured parts. Complementary mechanical characterizations showed an orientation-dependent influence of the applied energy density on emerging mechanical properties, correlated with geometry-dependent temporal process characteristics that implicitly influence the available coalescence time and the timespan available for the thermal homog-enization.

Vortragssprache: ENG